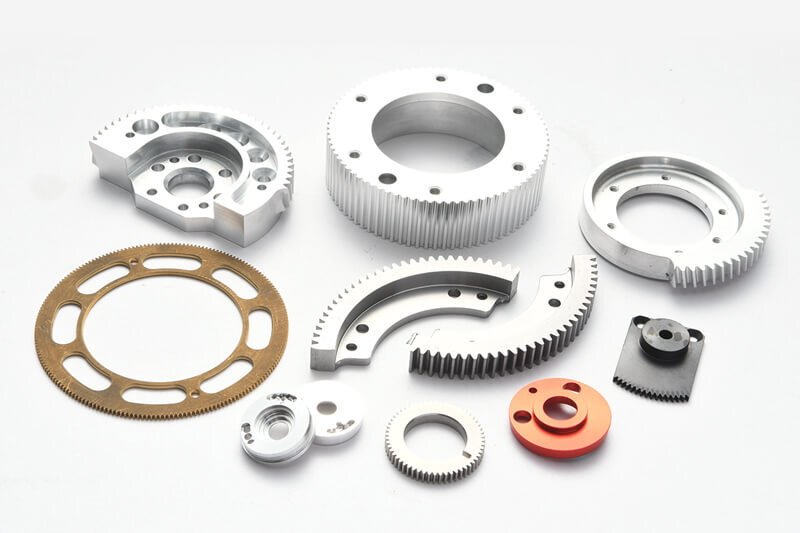

Precision Gears (Spur, Helical, Bevel, Segments)

Spur Gear

Our Capability

1) Gear accuracy (I.e Lead and Profile) up to 0.0025mm

2) Material: Brass, Bronze, Alloy Steel, stainless Steel and Alumnium

3) Produced according to international standard JIS, JGMA, AGMA, ISO & DIN

4) Max Outer Diameter ⌀120mm

5) Customizing gear/special gear upon requested by user/client.

6) Reverse Engineering capability.

7) Inspection reports available.

Helical Gears

Our Capability

1) Helix angle : ~55Deg (left or right)

2) Gear accuracy (I.e Lead and Profile) up to 0.0025mm

3) Material: Brass, Bronze, Alloy Steel, Stainless Steel and Alumnium.

4) Produced according to international standard JIS, JGMA, AGMA, ISO & DIN

5) Max Outer Diameter ⌀120mm

6) Customizing gear/special gear upon requested by user/client.

7) Reverse Enginnering capability

8) Inspection reports available

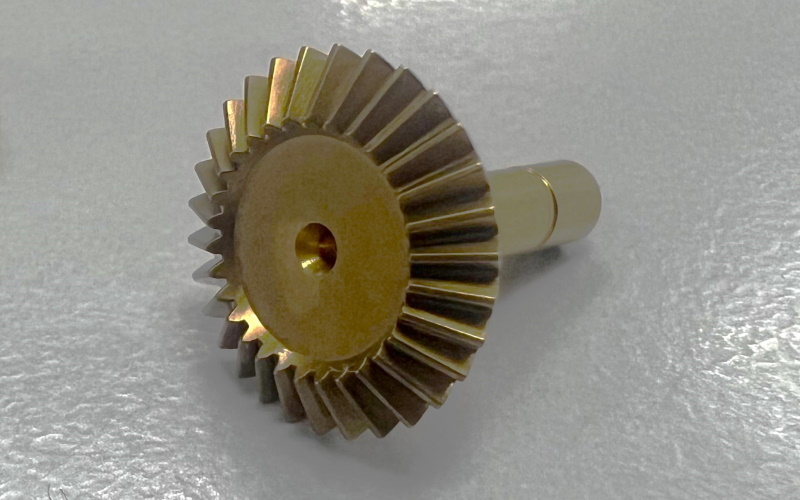

Bevel Gear

A business collaboration with bevel manufacturer locating in Bangalore India on bevel fabrication.

1) Straight & Spiral

2) High reduction Hypoids (HRH®)

3) Produced according to international standard JIS, JGMA, AGMA, ISO & DIN

4) Customizing gear/special gear upon requested by user/client.

Segment Gear

Our Capability

1) Helix angle : ~55Deg (left or right)

2) Gear accuracy (I.e Lead and Profile) up to 0.0025mm

3) Material: Brass, Bronze, Alloy steel, Stainless Steel and Alumnium.

4) Produced according to international standard JIS, JGMA, AGMA, ISO & DIN

5) Customizing gear/special gear upon requested by user/client.

6) Inspection reports available.